ShenZhou rubber and plastic products co., LTD is specializing in the production of rubber insulation materials manufacturers. Company continuously introducing advanced technology at home and abroad carry on the improvement of self digestion, was provided for the existing equipment, technology innovation, and always maintain the leading level in the industry. Products have passed SGS certification, the BS476-1997 test, South Korea KS, FM certification, national product quality tracking, annual production capacity of 700000 cubic meters, the scale of production, market coverage are among the top of the national industry.

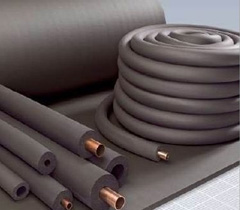

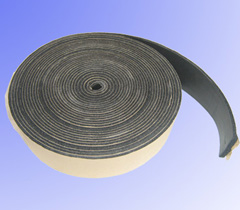

- Product display

- Performance is introduced

- Technical indicators

- Testing instrument

- contact

|

|

|

|

|

|

one: the low thermal conductivity

When the average temperature of 0 ℃, this material coefficient of thermal conductivity is 0.034 W/mk, and its surface exothermic coefficient is high, so in the same external conditions, the use of this product thickness more than half than other heat preservation material can achieve the same effect of heat preservation, thereby saving the ceiling above the floor, save investment.

two: flame retardant performance is good

This material contains a large amount of flame retardant smoke reduction material, produced by the combustion smoke density is extremely low, and in case of fire don't melt, don't drop the burning fireball, materials since the quench characteristics.

According to GB8624-1997 "building materials combustion performance grading method", this product is a B1 level flame retardant materials, to ensure safe and reliable.

Three: closed-cell foam, moistureproof performance is good

1: glass fiber: open pore structure high water vapor permeability, leading to longer duration of use, also with higher thermal conductivity, the heat preservation effect is reduced greatly.

2: foaming polyethylene (PEF) : even the pore structure, has a high water vapor permeability, the material of hard and brittle, easy breakage and short service life.

3: China rubber: obturator structure with minimal water vapor permeability, can keep the low coefficient of thermal conductivity for a long time.

Four: good seismic performance

Shenzhou rubber insulation material with high elasticity, and thus can minimize chilled water and hot water pipes in the process of using vibration and resonance.

Five: flexible performance

China rubber and plastic materials with good strength and toughness, bending and irregular pipe construction of easy processing, and can save material.

Six: easy installation, beautiful appearance

Because this product is rich flexibility, easy to install and convenient. Pipe installation: can be put on after the installation together, also can use this glue of the reoccupy after pipe lengthwise. The valve, tee, elbow and other complex components, can clean the plate after cutting, according to the different shapes on the package glue, to ensure the rigor of the whole system, thus ensuring the heat preservation of the entire system. And because of this material are rubber surface smooth level off, and the excellent properties of itself, does not need additional steam insulation layer, protective layer, reduce the trouble of construction, also ensure the beautiful appearance, smooth.

When the equipment or pipeline maintenance, stripping down the material can be reused, performance remains the same.

seven:Other advantages:

China rubber insulation is very safe to use and will not stimulate the skin, also not a health hazard. They can prevent mould to grow, avoid pests or mouse bite, and acid and alkali resistance, superior performance. These performance ideal makes the shenzhou rubber protection pipe insulation, prevent them from corrosion by atmospheric medium or industrial environment.

| Project | units | performance | standards | ||

| Apparent density | Kg/m3 | ≤95 | GB/T 6343 | ||

| Combustion performance | oxygen index | % | ≥32 | GB/T 2406 | |

| Smoke density | —— | ≤75 | GB/T 8627 | ||

| When used in construction field, not below C level | GB 8624-2006 | ||||

|

Coefficient of thermal conductivity The average temperature -20℃ 0℃ 40℃ |

W/(m.k) |

≤0.031 ≤0.034 ≤0.036 |

GB/T 10294 | ||

| Moisture permeability | coefficient of permeability | g/(m.s.pa) | ≤2.8×10-11 | GB/T 17146-1997 | |

| The wet resistance factor | —— | ≥7.0×103 | |||

| Vacuum suction rate | % | ≤10 | GB/T 17794—2008 | ||

|

Dimensional stability 105±3℃, 7d |

% | ≤10 | GB/T 8811 | ||

| Tear strength | N/cm | ≥2.5 | GB/T 10808 | ||

|

Compression spring rate The compression rate is 50% The compression time 72 h |

% | ≥70 | GB/T 6669-2001 | ||

|

The ozone resistance The oxygen partial pressure 202 mpa 200h |

—— | not cracked | GB/T 7762 | ||

|

Aging resistance 150h |

—— | slight wrinkle, no crack, no pinhole, deformation | GB/T 16259 | ||

| Suitable temperature | ℃ | -40—110℃ | GB/T17794 | ||

Pipe products specifications

|

The brass Outer diameter (inches) |

Seamless tube Outer diameter (mm) |

Galvanized pipe Nominal DN |

shenzhou Rubber and plastic The inner diameter (mm) |

9mm thick(1.8m/root) | 15mm thick(2m/root) | 20mm thick(2m/root) | 25mm thick(2m/root) | 30mm thick(2m/root) | ||||||

| Specifications(mm×mm) | The root / | The root / box | Specifications(mm×mm) | The root / | Specifications(mm×mm) | The root / | Specifications(mm×mm) | The root / | Specifications(mm×mm) | The root / | ||||

| 1/4 | 6 | 6×9 | 180 | 180 | ||||||||||

| 3/8 | 6 | 10 | 10×9 | 140 | 140 | 10×15 | 80 | 10×20 | 70 | |||||

| 1/2 | 13 | 13×9 | 120 | 100 | 13×15 | 80 | 13×20 | 50 | ||||||

| 5/8 | 14 | 8 | 16 | 16×9 | 100 | 95 | 16×15 | 60 | 16×20 | 50 | ||||

| 3/4 | 19 | 19×9 | 100 | 80 | 19×15 | 60 | 19×20 | 40 | ||||||

| 7/8 | 22 | 15 | 22 | 22×9 | 100 | 70 | 22×15 | 60 | 22×20 | 40 | 22×25 | 30 | 22×30 | 25 |

| 1 | 25 | 25 | 25×9 | 80 | 55 | 25×15 | 60 | 25×20 | 30 | 25×25 | 25 | 25×30 | 25 | |

| 1 1/8 | 28 | 20 | 28 | 28×9 | 60 | 50 | 28×15 | 50 | 28×20 | 30 | 28×25 | 25 | 28×30 | 20 |

| 1 1/4 | 32 | 32 | 32×9 | 60 | 45 | |||||||||

| 1 1/4 | 32 | 34 | 34×15 | 40 | 34×20 | 30 | 34×25 | 25 | 34×30 | 20 | ||||

| 1 3/8 | 25 | 35 | 35×9 | 60 | 40 | |||||||||

| 1 1/2 | 38×9 | 50 | 30 | |||||||||||

| 1 5/8 | 25 | 42 | 42×9 | 50 | 30 | |||||||||

| 1 5/8 | 32 | 43 | 43×9 | 50 | 30 | 43×15 | 30 | 43×20 | 25 | 43×25 | 20 | 43×30 | 15 | |

| 1 7/8 | 40 | 48 | 48×9 | 50 | 28 | 48×15 | 30 | 48×20 | 25 | 48×25 | 20 | 48×30 | 15 | |

| 2 1/8 | 54 | 54×9 | 50 | 25 | ||||||||||

| 2 3/8 | 50 | 60 | 60×9 | 50 | 20 | 60×15 | 30 | 60×20 | 20 | 60×25 | 15 | 60×30 | 15 | |

| 76 | 70 | 76 | 76×15 | 25 | 76×20 | 15 | 76×25 | 15 | 76×30 | 10 | ||||

| 89 | 80 | 89 | 89×20 | 15 | 89×25 | 15 | 89×30 | 10 | ||||||

| 108 | 108 | 108×20 | 15 | 108×25 | 10 | 108×30 | 10 | |||||||

Plate (1.5 meters) wide

| The thickness | 10mm | 15mm | 20mm | 25mm | 30mm |

| m/a | 16m | 16m | 8m | 8m | 8m |

1. The above specifications are the commonly used specifications, if you need special specifications can be produced according to user requirements.

2. Black sheet, pipe, need special color according to user requirements can be produced.

3. It is recommended to use more than 89 mm pipe diameter.

4. The thickness of insulation materials need more than 25 mm, using multilayer overlapping packaging, until the required thickness.

5. The plate width can be customized according to user requirements 1-2 meters.

Install the required thickness of the CRT (due to the difference of regional environmental conditions, the following data is for reference only) :

| Environmental conditions | Thermal insulation pipe size | Line temperature suitable thickness (mm) | |||||

| The temperature(Temp) |

Relative humidity (Temp) |

inches(Inch) | mm | 13℃ | 7℃ | 3℃ | -15℃ |

| 26.5℃ | 50% | 3/8~3 | 10~76 | 10 | 10 | 10 | 15 |

| 3~5 | 76~127 | 15 | 15 | 15 | 15 | ||

| 5~10 | 127~254 | 15 | 15 | 15 | 20 | ||

| 29℃ | 70% | 3/8~3 | 10~76 | 10 | 15 | 15 | 20 |

| 3~5 | 76~127 | 15 | 15 | 15 | 20 | ||

| 32℃ | 80% | 5~10 | 127~254 | 15 | 15 | 15 | 25 |

| 3/8~5 | 10~127 | 15 | 15 | 20 | 20 | ||

| 5~10 | 127~254 | 20 | 25 | 25 | 35 | ||

| 32℃ | 85% | 3/8~1 1/2 | 10~38 | 20 | 25 | 30 | 45 |

| 1 1/2~3 | 38~76 | 20 | 30 | 30 | 50 | ||

| 3~5 | 76~127 | 20 | 30 | 35 | 60 | ||

| 5~10 | 127~254 | 25 | 30 | 40 | 60 | ||

| >10 | >254 | 30 | 40 | 45 | 70 | ||

| 32℃ | 90% | 1/8~1/2 | 3~13 | 25 | 32 | 35 | 45 |

| 1/2~2 1/2 | 13~64 | 30 | 35 | 45 | 60 | ||

| 2 1/2~5 | 64~127 | 30 | 35 | 45 | 65 | ||

| 5~10 | 127~254 | 35 | 45 | 50 | 75 | ||

| >10 | >254 | 35 | 50 | 60 | 75 | ||

Determine the thickness of heat preservation material factor:

1, the environment temperature is higher, the thicker the material;

2, the relative humidity is bigger, the material is thicker;

3, medium temperature is lower, the thicker the material;

4, the bigger the pipe diameter, the thicker the material.

|

|

|

|

|

|

|

|

|

Telephone: 0316-5199345

Fax: 0316-5199234

Mobile: 13831652499 15832688789

Address: Hebei province dacheng county To leave the town Industrial Park